Description

Common nail making machine factory

We can make the whole steel wire nail product line, such as nail polishing machine, nail grinder machine, steel wire drawing machine, butt-welding machine and roller tip machine. Our machine arrived in many countries like Bangladesh, Uzbekistan, India, Ukraine, Russia, Egypt and so on.

Nail making machine Introduction:

The Dingsheng brand nail making machine is designed to make 1-6 inch wire nails and steel nails.

Z94-4C Nail Making Machine Parameters (The hot sale model):

Nail Diameter: 3.0-4.5 mm

Nail Length: 40-140 mm

Motor Power: 4kw

Speed: 220 pcs/min.

Diemension: 2350x1480x1400mm

Weight: 1950 kg

Common Nails are mainly consist of three parts: a wide head, a smooth shank and a dimoud-shaped point.

The common Nail Head, Shank, Point are:1. Nail Head: Circular Flat, Double Head, Dimond Head, Spring Head

2. Nail Shank: Smooth Shank, Ring Shank, Screw Shank, Square Twisted Shank

3. Nail Point: Dimond Point, Dimond Point offset, Round Point

Steel wire for nails making:

1. Material: Original 6.5 mm in diameter Q195 & Q235 Carbon Steel

2. Frequency Conversion Wire Drawing Machine: To draw the original 6.5 mm Carbon Steel to small diameter wire rod like 4.5 mm, 3.8 mm, 3.4 mm, 2.8 mm. The quick-wear parts are: Different size drawing mould, drawing powder.

3. Nail Making Machine: Put the small diameter coiled rod on a wire reel, then feeding it into the common nail making machine. Our automatic nail making machine can form the Nail Head, Nail Shank, Nail Point with one time cutting. The quick-wear parts are: Nail Die Cutter, Nail Gripper Mould, Nail Punch Pin.

4. Nail Polishing Machine: Put the semi-finished nails into the polishing drums, it will remove the dust iron of the semi-finished nail surfaces. The finished wire nails are bright and surfaces are very smooth.

5. Nail Packing: Generally, there are two ways for packing the common nails, they are Plastic Bag Packing and Paper Box Packing. This is mainly depending on the final customer’s requirements and buying habit.

Nail Production Process:

The Process to make nails is :

We should draw the raw material of wire rods of 6.5mm or 5.5mm diameter (usually 2-3 tons per coil), to small wire coils (200-300 kg per coil) of diameter such as 4.5mm,4.1mm,3.4mm,2.8mm, etc needed for making nails by the wire drawing machine, after this, put the small wire coils on a wire reel, from which the steel wire was feed into the nail making machines to make nails, after the wire is cut to nails, it needs to polish the nails to remove the iron dust on the nail shaft and make it become bright and good looking, then packaging.

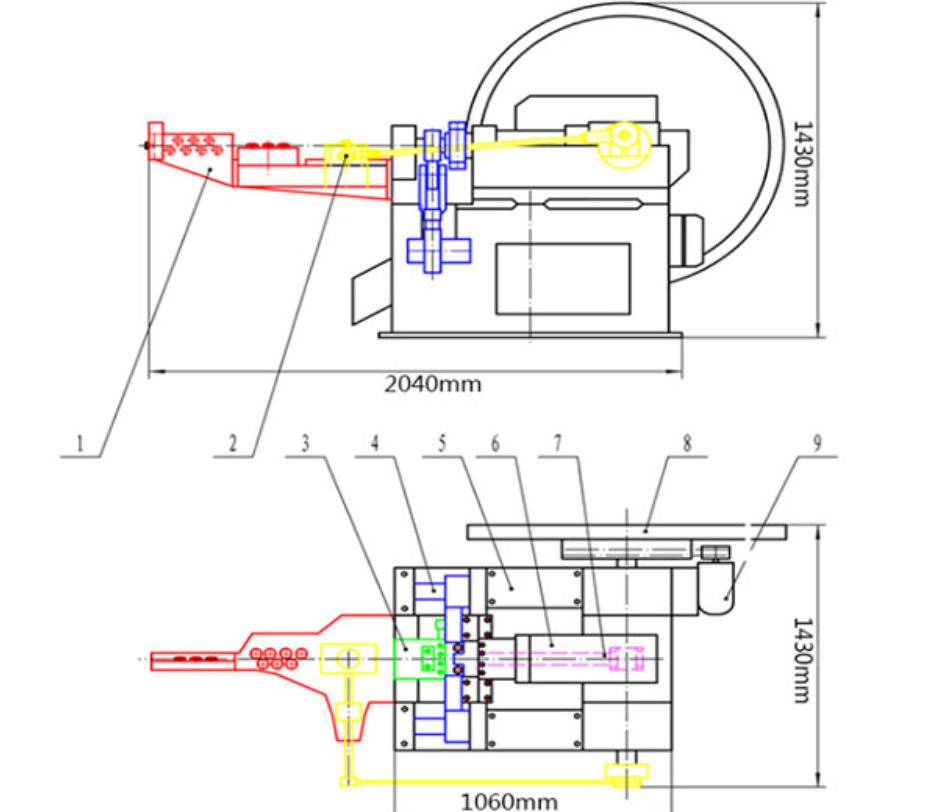

Steel Nail Making Machine structure:

The main structure of the nail-making machine, including the big wheel, mainframe, motor, discharge hopper, wire feeding mechanism, straightening mechanism, punching mechanism, mold mechanism, nail cutter cutting Mechanism, and gear transmission mechanism.

Nail Making Machine Working Principle:

The Z94 nail-making machine uses Taiwan nail-making technology, by straightening the wire, feeding the wire, cutting to form the nail tip, punching to form the nail cap, and so on to make nails.

The Z94 nail machine is a fully automatic machine for the production of wire nails. It is powered by a motor. There is a switch on the machine. After the machine is turned on, according to different wire diameters, a coil of iron wire can be used for 4-8 hours without stopping.

Z94 nail producing machine, controlled by a switch, works without a frequency converter and control cabinet, It is simple operation and speed non-adjustable.

| Model | Z94-1C |

Z94-2C |

Z94-3C |

Z94-4C |

Z94-5C |

| Nail length | 9-25 mm |

16-50 mm |

25-70 mm |

40-110 mm |

60-150 mm |

| Max nail dia. | 1.6 mm |

2.5 mm |

3.5 mm |

5.0 mm |

5.5 mm |

| Power |

1.5 kw |

2.2 kw |

3.0 kw |

4.0 kw |

5.5 kw |

| Speed | 380 pcs/min |

340 pcs/min |

300 pcs/min |

220 pcs/min |

220 pcs/min |

| Weight | 800 kg |

800 kg |

1100 kg |

1800 kg |

2200 kg |

| Dimension |

1500*1200*1200

mm |

1600*1250*1250 mm |

1900*1200*1200

mm |

2300*1390*1345

mm |

2400*1400*1350

mm |

Z94C series High speed ,low noise nail making machine usually used to make normal nail, concrete nail, stainless steel nail, D shape and T shape nail.

This type equipment is consist of lubricating system and driving system.

The driving system include wire feeding,wire clamping ,wire cutting and stamping.

Common nail making machine production line

Wire Drawing: Draw the wire rods from 6.5/5.5mm to a smaller diameter for example 4.5mm, 3.4mm for making nails.Generally, the 1-4 Inch Nail Making Production Line and 1-6 Inch Nail Making Production Line are the popular choices for our clients. More than 80% foreign clients choose to manufacture the 1-4 Inch common nails or the 1-6 Inch common nails.

Below are the proposals for setting the Basic Nail Making Factory:

1-4 Inch Nail Making Production Line:

Nail Making Machine Z94-2C

Nail Making Machine Z94-4C

Nail Polishing Machine with capacity 1000 kg

Nail Mould Grinding Machine

1-6 Inch Nail Making Production Line:

Nail Making Machine Z94-2C

Nail Making Machine Z94-4C

Nail Making Machine Z94-5C

Nail Polishing Machine with capacity 1000 kg

Nail Mould Grinding Machine

What types of nails can be made:

Our nail making machine can make wire nails, steel nails, coil nails, concrete nails, and big cap nails.

![]()

![]()

common nail making machine, 1-4 inch nail production line, 1-6 inch nail prodiction line